Since the release of SYSPRO’s Manufacturing Operations Management solution (SYSPRO MOM), I’ve spent many hours explaining to customers the difference between MOM and MES (Manufacturing Execution Systems). The terms are used so that they generate more than their fair share of confusion.

The differences between MOM and MES

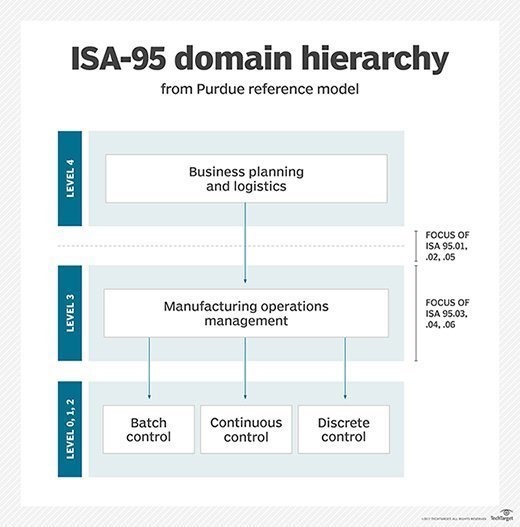

Both terms describe the technologies that occupy the space described by ISA-95 as ‘Level 3’, as pictured in the diagram below. The acronym ‘MOM’ replaced ‘MES’ for a variety of reasons, including the fact that the concept of ‘Execution’ does not sit as well with process manufacturing as it does with discrete manufacturing.

MOM (despite her grey hairs) is also a little younger than MES and was created to be inclusive of solutions that evolved to fit in the same space, including functionalities that don’t strictly fit the original description of MES, such as quality, inventory, production management, enterprise manufacturing intelligence, and myriad other advanced technologies.

The debate over nomenclature continues, but these days, the term MES is often used by vendors because it’s familiar, even though their solutions might be more properly referred to as a MOM.

As a technology pioneer in the vanguard of Industry 4.0, SYSPRO has embraced the newer and less ambiguous acronym “MOM”. MOM technologies help to future-proof businesses by embracing Industry 4.0 opportunities, through the strategic adoption of technologies and protocols that provide the digital foundation for the highly-automated Smart Factory.

The advantages of MOM/MES for manufacturers:

Let’s not bog down in a technical debate – we can safely consider MOM and MES to be similar. So now we can begin to look at the advantages that MOM/MES brings to the problems of manufacturing.

To start with, it’s an important fact that a thoroughly modern MOM should be ‘device agnostic’. That is, any device (PCs, laptops, tablets, smartphones, etc.) should be able to interact with MOM, as long as it can open and run a browser. As the number and utility of devices proliferates, this becomes an increasingly important feature, allowing companies and individuals to customize and optimize their user experience. Although it may seem relatively inconsequential in the overall manufacturing organization, device agnosticism is an important step towards future-proofing your factory.

MOM’s guiding hand brings business-wide benefits. At a quick glance, MOM can provide significant help in:

- Delivering finished goods faster to customers

- Controlling labour and machine costs,

- Reducing downtime and bottlenecks

- Increasing productivity and output

- Measuring and improving product quality

- Eliminating waste

- Driving Lean and continuous improvement programs

- Reducing operation costs.

MOM provides these benefits by collecting production information, over multiple plants, and by integrating easily with equipment, controllers, and ERP. The result is business-wide visibility and control, as well as the optimization of production activities from customer order to finished goods.

In my next blog, I will dive deeper into the advantages of MOM functionality in manufacturing businesses continue their digital transformation.

I continue to explore MOM’s functionalities and advanced manufacturing benefits in detail for the smart factory.