Manufacturing leadership was under tremendous pressure before the pandemic to provide growth and profitability in a highly competitive market. Then the pandemic upended everything, throwing manufacturing and the supply chain into chaos. One of the keys to regaining is building relationships with key stakeholders: internal people, customers, prospects, and partners.

But first, we need to address the current state of affairs. How much chaos did the pandemic create, really? To answer this question, SYSPRO conducted a large survey of manufacturing and distribution executives in August 2020. The results were eye-opening. Six out of ten said they’d experienced supply chain disruptions. Nearly half (47%) couldn’t function because staff had to be on-site to access the software they required. And just under a quarter (23%) were worried that parts shortages would prevent them from meeting market demand with enough supply.

Overcoming chaos requires accurate, reliable, consistent information. So, naturally, manufacturing and distribution executives have responded by accelerating their digital transformation efforts. After all, one of the main goals of digital transformation is to digitize operations so they can provide accurate, insightful, actionable information on which to base decisions. According to Fictiv’s 2021 State of Manufacturing Report, 91% of manufacturers increased their investment in digital transformation over the past year.

Nevertheless, the process of digital transformation can introduce its own unique kind of chaos if not managed properly. Manufacturing executives need to control the chaos so they can lead their organizations into a profitable and growing post-pandemic future. One of the keys to accomplishing this goal of control is building relationships with key stakeholders: internal people, customers, prospects, and partners.

The six key risks for manufacturers in 2021

SYSPRO recently published an eBook, Chaos vs. Control: A Tactical Guide to ERP, that lays out the six primary risks manufacturers face and how executives can use ERP to address them:

- Competition: Manufacturers today not only have to produce high-quality products, but they also need to ensure reliable, fast delivery and an increasingly high level of customization. Balancing the risk between having enough product in stock to meet demand vs. a warehouse full of obsolete products is getting trickier all the time.

- Scalability: The market moves fast, but entering a new market opportunity is risky unless the manufacturer can scale up or down quickly.

- Execution: With so little room for error, leadership has to keep a close eye on operations, tracking work in progress, production, labor, materials, deliveries, and scrap. Increasingly, executives want to prevent problems before they cause significant disruptions. Those organizations that are constantly responding to crises are losing.

- People: The labor market is heating up as the economy starts to recover from the pandemic, and with remote and hybrid work becoming the norm, manufacturers are no longer tied down to a 50-mile radius of their facility or office for many positions. Competition for talent is going to be intense.

- Uncontrollable external forces: Gyrations in the world economy, natural disasters, and global pandemics — these are enormous agents of chaos that simply cannot be controlled.

- Transformation: Digitizing a business is a complex, ongoing process, and while it’s a necessity, any endeavor this complicated will cause some disruption and pose some risk.

Risk mitigation through communication and good information

All of these risks share two commonalities. The first is that they’re complex issues that require strong relationships and good communication between multiple stakeholders. For instance, a manufacturer can’t rapidly scale up and down unless finance, sales, and operations management have access to accurate, timely, consistent information. But that’s not enough. Suppliers need to be in the loop so they can adjust, and it’s critical to keep customers informed to manage expectations.

Likewise, managing production and inventory to meet demand without building up a hefty backstock of soon-to-be obsolete products requires accurate data about demand, supply, parts availability, production, and more. And it all needs to be shared so each stakeholder can plan and execute their responsibilities efficiently. This ability becomes even more important when global shocks like a pandemic occur. Those manufacturers who built digital systems that can manage the complexities of dual sourcing will be much better prepared to weather the crisis than those that haven’t.

The second common thread is timely, accurate, consistent data.

You’ve probably heard many times from pop psychologists that the key to strong relationships is good communication, and that holds true in business as well. But good communication is more than just sharing information; in business, it requires sharing accurate, timely information. People can’t make good choices in void. Modern business requires data-based decision-making, which, in turn, requires a single, trustworthy version of the truth.

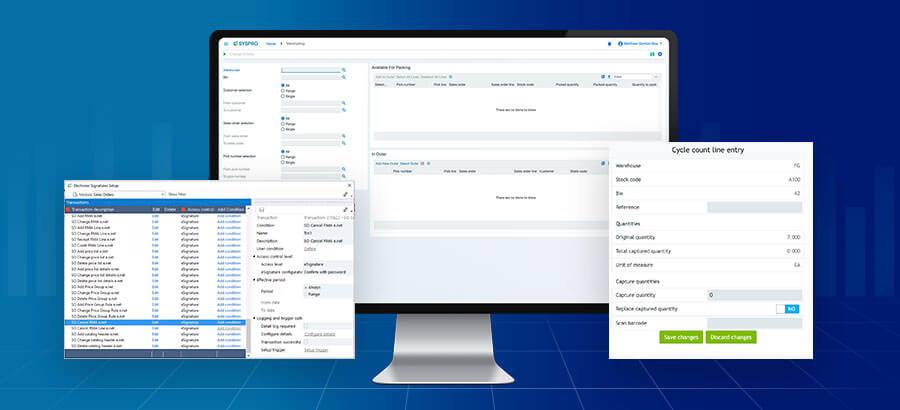

That’s the job of the ERP. That’s why it’s so critical to have a platform that’s specifically designed to tackle the unique challenges of your industry and provides a flexible architecture so it can easily integrate with other critical systems. The ERP is the foundation for digital transformation, serving as the information hub, the single source of truth and trusted information. With a strong manufacturing ERP platform in place, your organization will have taken an important step toward good communication with stakeholders and addressing the six key risks for manufacturers in 2021.