It is no secret that the manufacturer and distributor sectors have been some of the hardest hit by the global health crisis and recent geopolitical instability. In many cases this has forced decision-makers to take a step back and reassess the bigger picture and implement changes where necessary to meet the growing need for agility and resilience.

At the center of many of these changes is a re-tooling which has seen the integration of key digital technologies designed to help businesses cope with changing demands and climates. Tackling the various hurdles faced by manufacturers and distributors requires a strategic approach.

Below are four recalibration tactics decision-makers looking to adopt a growth mindset should consider integrating into their strategies to drive growth and maintain relevance now and in the future.

Implementing innovative cost-saving for a manufacturer

Rising inflation has been a top concern for many in the manufacturing and distribution industries. The growing costs of materials, goods, shipping, and more have had tangible adverse effects on operating costs, output levels, and ultimately profitability across the industry.

Manufacturers and distributors have had to seek out innovative ways to save on costs while remaining competitive. Some have turned to buying in bulk, leaning on the opinion that costs will continue to rise. However, this is a less-than-ideal approach that holds substantial risk, especially in the short term. The lack of cash flow inherent to this approach means lowered agility while stockpiled resources increase the potential for spoilage and wastage due to damage or obsolescence.

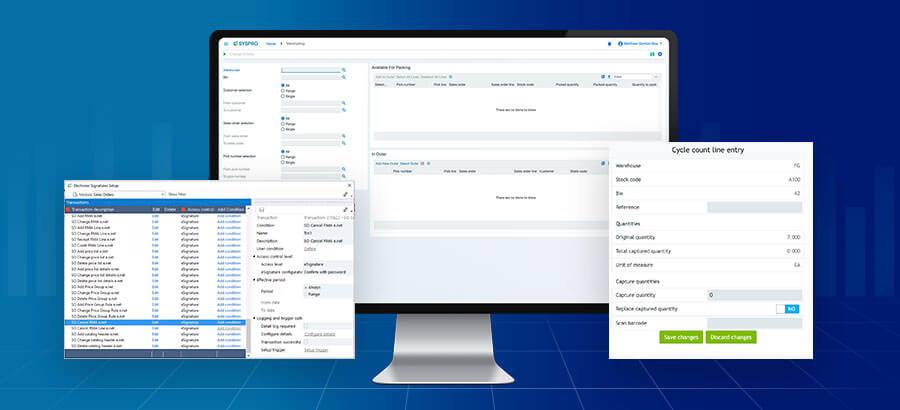

Others are turning to technology in the form of ERP technology. ERP systems have allowed these businesses to lower costs by automating labor- and time-intensive tasks reducing the hours and expenses spent on task completion. This is a far less risky approach that builds business resilience to economic shock, rather than lowering it. For example, ERP software can provide decision-makers with insights into the seasonality of products and customer-buying habits in the current market. This automatic feedback ensures businesses are up-to-date with trends and ensures the correct inventory is stocked at the correct times. This saves users millions in operational costs and helps build a stable, sustainable supply source.

Entering the digital economy

Embracing smart technology is becoming a necessity. Technology such as ERP software is key to providing decision-makers with actionable, real-time insights on areas such as customer-buying patterns and market trends. In an age where volatility is the norm, this data is key to effective risk-management planning. Artificial Intelligence (AI) insights can also help businesses absorb macro-economic shocks and deal with localized operational shocks like equipment failures in a proactive manner.

ERP allows businesses to boost agility, and therefore productivity and cost efficiency, across all business areas. Key to harnessing this lies in data extraction and management rooted in AI. ERP Chatbots, for example, automate intelligent data sourcing by retrieving business-relevant insights from their environments to inform decision-making in key client-facing departments like sales and marketing. Beyond this, they also free up human resources to handle customer queries and analyze interactions for better customer experience.

Take advantage of shifting employment trends

While remote work may have initially caused disruptions in work continuity and productivity, this need not be the case. As it seems remote and hybrid working are here to stay, embracing a different way of working is key. But while remote working may have initially been viewed as disadvantageous, it has highlighted the need for leaders and employees to have the resources they need, such as real-time data, no matter where they are working from.

For example, having instant access to up-to-date sales and service information during off-site customer interactions gives employees the ability to address concerns as they arise and respond to queries with confidence, maintaining and improving client relationships. Smart technology such as mobile ERP software gives manufacturers and distributors this kind of improved business agility. Their teams can securely access a plethora of information from across the entire business on any device, rather than being pigeonholed to their usual direct business needs accessible only via their work device.

Prioritizing digital security for a manufacturer

Downtime due to cyberattacks is rapidly becoming a top concern. Cybercrime has grown exponentially over the last three years with consequences spanning beyond the risk of downtime. As the value of data increases, loss of protected business and customer data has a profound impact on customer loyalty and reputation. This is especially true of the manufacturing sector which continues to be a top target in 2022. Maintaining a handle on your digital attack surface through proper security measures and regular reviews is critical to avoid becoming a victim.

However, for many ensuring the adequate protection of their numerous business programs is a challenge. ERP software paired with a reliable vulnerability management (VM) application can offer significant help when it comes to staying on top of the expanding digital attack surface. By bringing all your business software and data under one umbrella, ERP software offers improved security through intrinsic controls and centralized back-ups of data.

As global volatility continues to plague markets and issues around supply chains still front of mind, decision-makers in the manufacturing and distribution sectors have been tasked with future-proofing their businesses. To realize their goal of creating resilient businesses, decision-makers need to take a strategic approach. Short-term investment in smart ERP technology is key to garnering long-term tactical advantages. It is only through embracing this technology that businesses can expect true long-term success.