A few months back, I wrote a blog entry comparing the uncanny similarities between building your own furniture and ERP selection. Reflecting back on that post, I decided to brainstorm additional daily/real-life scenarios that can also be compared to daily struggles that manufacturers and distributors face within their own businesses. What was the next issue I decided to address? Inventory management and, well…baking a pumpkin pie.

We just celebrated the Thanksgiving holiday in the US and as my mother prepared to host her annual celebration, she asked me to bring my famous homemade pumpkin pie for dessert. We were inviting more people to dinner than we have in past years, and because of this I offered to make two. Since pumpkin pie is my specialty, I usually keep plenty of the ingredients stocked in my cabinet all year long. However, I will be making double this Thanksgiving, so I needed to check my pantry’s inventory to see if I had enough ingredients to make both pies. I generally anticipate making a few pies each year and I had just the correct amount of sugar, cream, pumpkin puree and pie crust to make two and therefore didn’t need to go to the grocery store for additional ingredients. Unfortunately, little to my knowledge, my husband also agreed to make a pumpkin pie for his family’s thanksgiving celebration and the ingredients in my cabinet were already accounted for.

While at the grocery store on Thanksgiving morning, I got to thinking about how my situation with the shortage of ingredients and “limited visibility” of my pantry’s inventory could be compared to the manufacturing and distribution industry. In order for a business to function properly and to keep high levels of customer service, it’s important to have complete visibility into your inventory and a fully-integrated inventory management system.

The MRP (material requirements planning) tools in ERP software enable manufacturers and distributors to decide when to make the product, what resources to use, when to order materials and components, and to specify the production sequence to improve throughput. Good ERP software provides all the facilities to control both short and long production runs. Since the batch size of a particular product can vary from a few units to several thousand units, the software will calculate the elapsed time of an operation or job.

I realized that a system like this is what I need to manage the inventory in my pantry so I had everything I needed for baking. If I had access to real time data when jobs (pies) are created (committed to other parties) and therefore showed accurate stock levels, I would have known that my husband had already committed the ingredients for another pie and I wouldn’t have been scrambling to make a pie on Thanksgiving morning.

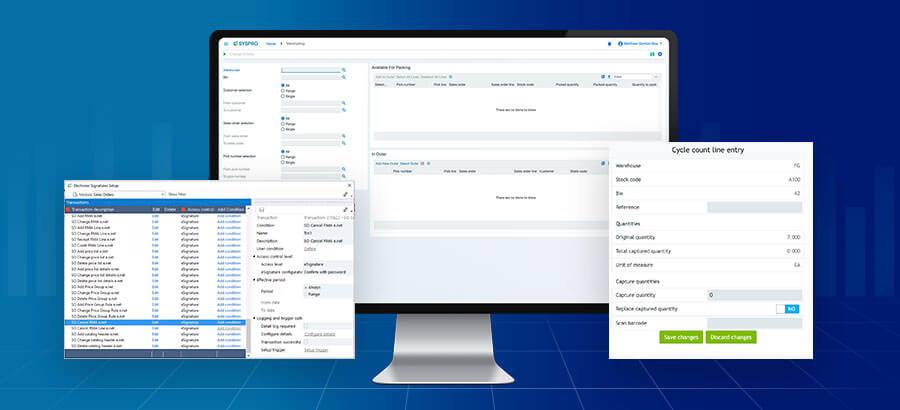

To get a little more knowledge, I looked at SYSPRO’s Inventory Optimization, which understands the four key steps to optimal inventory management:

Categorize SKUs

SYSPRO analyzes stock codes according to their impact on profitability, revenue generation, and historical supply and demand behavior. This identifies critical items that require detailed forecasting. An analysis of the behavior of items over time determines seasonal fluctuations.

Forecasting

The forecasting process enables an organization to forecast customer demand by item; the main driver of sound inventory planning. This process should be fine-tuned over time, using actual past data to ensure future forecast accuracy.

Determining stock policies

Stock policies are modeled to determine the best balance between customer service and inventory investment. A key outcome of the policy is safety stock – this is required to ride-out unpredictable fluctuations in demand caused by events such as strikes or natural disasters.

Replenish according to plan

Software solutions are available to ensure the timely replenishment of stock according to the forecasting policy.

Based on my experience, I’ve come to a conclusion: In even the simplest manufacturing business like my tiny kitchen, the management of inventory is complex and necessary. But, while having the SYSPRO Inventory Optimization system manage my pantry may be overkill, having a best in class SYSPRO ERP System to manage inventory in your business is an absolute necessity.