Organizations today operate in a dynamic continuum where the rules of competition and operation are constantly evolving. No industry is immune to the effects of their organizational ecology to properly understand the mechanisms of different manufacturing industries. We cannot just compare the resiliency and responses of segments of the same industry.

Regional Processing Manufacturing

Plastics and rubber manufacturing is categorized under the second largest manufacturing group globally, ‘Regional Processing’, as they are located close to demand points and sources of raw material. Yet the industry displays certain needs which are characteristic of global innovation industries due to the lower level of R&D intensity, high labor intensity, low energy intensity and low value density when compared to other peers in the regional processing group such as fabricated metals and food and beverage. This presents unique challenges for the plastic and rubber industry which has evolved over time and requires a constant pursuit of inflection points to ensure sustainability and relevance.

One of the major industry challenges is the regulation and environmental protectionism laws. With the overlap of distinct technological revolutions – Industry 4.0 and the digital economy – and the additional regulatory changes, the industry is at the epicentre of new age manufacturing processes, with innovation and renovation being key for organizations navigating through these changes.

The Challenge of Cost Efficiency

A further challenge for the plastics and rubber industry is that of cost efficiency. The competitive factors in the plastic and rubber industry are based on level of technology adopted, scale of operation and market size. However, in recent years, the increase in the prices of raw materials has indirectly transferred to consumers, also making the manufacturers trim their profit lines. This is also the result of globalization, making substitute suppliers proliferate and creating further macro-economic issues whereby manufacturers cannot compete with optimal production capacities.

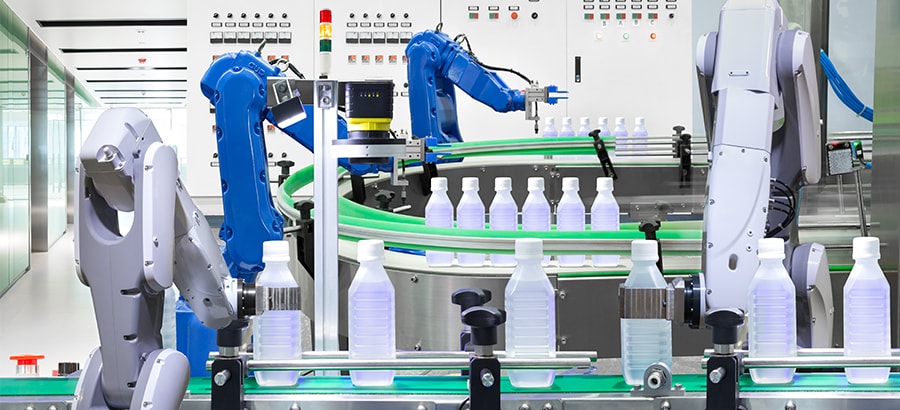

These challenges offer opportunities to create efficiencies and improve their processes by both digital transformation and automation. Some of which include:

- Manufacturing and operations management (MOM) – a robust platform that optimizes manufacturing processes and reduces costs

- Traceability – traceability solutions can enhance the entire value stream by providing visibility to the upward and downward stream characteristics, reducing risk, and enabling a cradle-to-grave traceability solution

- Supplier self-management – empower supplier and organizations by automating quotations, supplier maintenance, invoicing and inventory checks to enhance and improve delivery performance

- AI – the introduction of “what if scenarios” can enable organizations through better informed data-driven decisions as well as improving production scheduling

The plastics and rubber industry can improve operational mechanisms by adopting global industry innovations which can be delivered by an ERP system that truly understands manufacturing.