It is clear, South Africa’s manufacturers are not running at full capacity. In fact, according to Statistics South Africa, the industry is running 18.7% below capacity, showing a 3.2% decline in June 2019.

So, what’s the missing link? Well, according to The Mobile Corporation in South Africa 2019 study conducted by World Wide Worx, in partnership with SYSPRO, local manufacturers have fallen behind the curve of rapid advances in connectivity that make emerging technologies possible.

Despite general business services making use of basic mobile technologies, the trend drops off, with only 33% of manufacturers in the country saying they use advanced tools from basic mobile technologies.

In the face of Industry 4.0, South Africa’s manufacturing industry needs to be transformed into a truly high-tech sector. Forming part of the next-generation industries, smart manufacturing will be in major demand with profits to be made, but this will involve leveraging new technology that enables connectivity and mobility.

Mobility Gains Momentum

Mobility is gaining increasing prominence as a concept of Industry 4.0; this is echoed by the fact that 86% of manufacturers rank cloud computing as important for operations.

With mobile technologies revolutionizing the manufacturing industry and bringing greater accuracy and speed to production centers, enhanced efficiency has resulted in increased responsiveness, communication and collaboration. Many manufacturers are integrating mobile customer relationship management (CRM) systems to improve customer responsiveness, pricing and order fulfillment.

Mobile CRM adoption allows manufacturers to respond to customers in real-time. Yet, only 44% of manufacturers view CRM as essential business software.

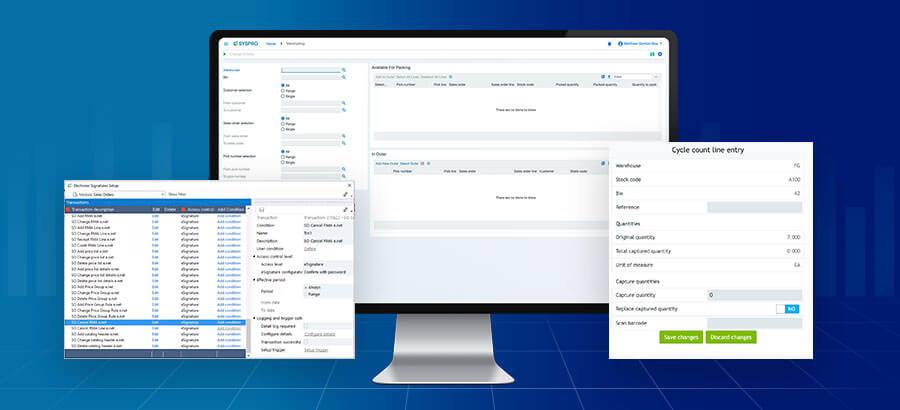

Mobile software for information sensitive systems, such as Enterprise Resource Planning (ERP), allows manufacturers and employees to improve quality of service to customers by providing them with access to relevant information while increasing productivity, planning, forecasting, and budgeting. And this is all available at the touch of a button.

But in South Africa, only 69% of manufacturers view ERP as essential.

Connectivity is Becoming Critical

To enable mobility, connectivity becomes somewhat of a prerequisite. The growing need for constant connectivity can be linked to growing demand for cloud computing, and cloud collaboration tools such as ERP solutions in the cloud.

With an influx of devices, all of which are becoming increasingly interconnected, the Internet of Things (IoT) is playing an increasingly important role.

So much so those global manufacturers will invest $267 billion in IoT solutions by 2020, according to Business Insider. This will lead to smart manufacturing which uses IoT and the Industrial Internet of Things (IIoT) devices to improve productivity and efficiencies of manufacturing operations.

However, the manufacturing industry places less value on today’s devices compared to other industries, with only 73% placing importance on mobiles, 63% on fibre optic connection, 64% on desktop computers, 63% on laptops, 45% on office Wi-Fi, 35% on ADSL connection, 36% on smartphones, 23% on mobile Wi-Fi, 16% on tablets and 5% on public mobile radio.

It’s All About the Data

Tapping into business intelligence (BI) and data analytics software allows real-time transparency of production chains. Manufacturers that are data-driven will see increased productivity and profitability, with greater synchronization of incoming and outgoing processes with stakeholders.

Predictive maintenance reduces machine downtime by 30 to 50% according to McKinsey, while Forbes suggests analytics reduces breakdowns by 26%. Plus, a study by LNS Research and MESA International revealed that analytics can improve the forecast of product demand and production by 46%.

However, local manufacturers fall short in comparison to other industries in the adoption of BI and analytics software, with only 34% considering these important.

Tying It All Together

Manufacturers must be agile to respond to market demands without increasing costs and waste or sacrificing efficiency.

To unlock the sector’s potential, manufacturers should seek an all-in-one solution that provides them with both mobility and constant connectivity.

For example, SYSPRO ERP offers a number of solutions that enable mobility and leverage IoT, such as SYSPRO Espresso and SYSPRO Cloud ERP.

And with SYSPRO’s Manufacturing Operations Management solution and software manufacturers can become leaner and improve profitability.

All-in-all, equipping manufacturers with the agility they need to respond to market demands without increasing costs and waste or sacrificing efficiency.