Before COVID, new technologies in manufacturing took years, sometimes decades, to become fully accepted. The pandemic, however, has speeded up those transitions by years. If you want to argue that these changes are in technology only, there was a recent Bloomberg article which noted that:

“companies from noodle makers to semi-conductor giants are spending on new plants and machinery in ways they haven’t done for years.”

Currently, much of the industrial world is like the consumer world was before cell phones become “smart”. As manufacturers invest in new technology equipment, it is going to enable smarter manufacturing. There are companies in every industry that are already embracing the reality of Industry 4.0 in which factories are digitally transformed, manual processes are replaced with automated systems, and factories and supply chains are smarter.

Various scenarios have been painted by analysts and consultants, but here is the consensus on where manufacturing is going.

The 4th generation manufacturing environment

The common themes around manufacturing trends point to these changes.

- Shift to a service-oriented business model

- Integration from the top floor to shop floor, and across the supply chain

- The digital factory

- Manufacturers thriving on data

- Proliferation of the Industrial Internet of Things

Equipment as a Service

As I explained in a previous blog, this is a business model where manufacturers have ongoing responsibility for the equipment after it is sold. Customers pay for the use of equipment through recurring operating charges rather than purchasing outright. This combination of physical products and digital services allows for unique product offerings to be offered to B2B customers.

The manufacturing platform

In the pre-COVID era, the value chain was the key, in the new era it will be the platform. This is a combination of interoperable standards and systems that provides integration of the shop floor with the rest of the business.

Information on new products or changes will be passed automatically to production planning and operations to ensure products are manufactured under agreed processes to the correct specifications. Product designs will be shared to locations around the world, enabling distributed manufacturing. This means that products can be made closer to the customer.

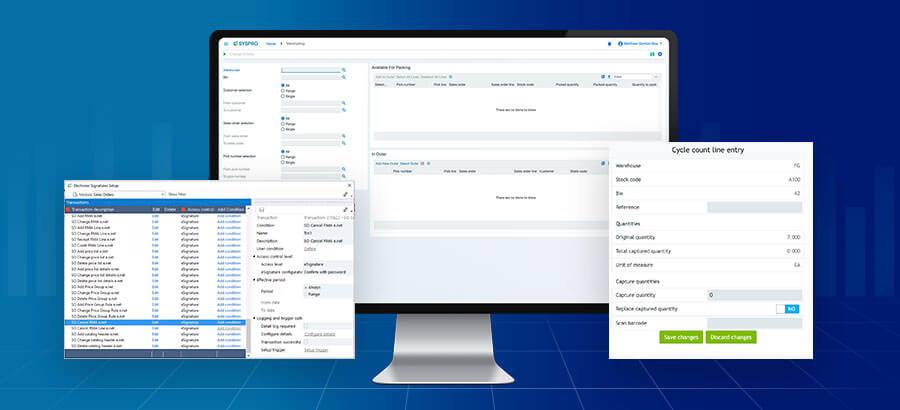

Systems like Manufacturing Operations Management (MOM) will use data from around the factory to enable all departments to collaborate on optimizing operations, and link the factory floor with the planning and execution functions of the ERP system.

The online technology we have all seen explode since 2020 can be applied to manufacturing ecosystems. In manufacturing, ecosystem partnerships can enable all types of initiatives – from collaborating with suppliers on product design, to smarter fulfilment strategies that require smaller warehouses, analytics that allows better decisions on when and what to order, and even environmentally friendly packaging.

Two years ago the concept of digital twins was at the very early stage of manufacturing technology. Now with cloud computing firmly established as the new normal, it is quite possible to start a smart factory project where the real manufacturing environment is replicated exactly in a virtual world. A manufacturing digital twin architecture is a digital model of the shop floor which allows the simulation of ‘what if’ scenarios before actual implementation happens. This allows manufacturers to:

- plan assembly lines to optimize the use of available physical space,

- simulate processes to identify potential process or quality,

- adjust and optimize production,

- decide how to carry out unplanned maintenance on machines.

Digital factory

In a digital factory, artificial intelligence (AI), business process management and analyzing data are integrated. The automation capabilities enabled by AI can improve efficiency and productivity. AI-powered applications can propose new solutions to operational issues. Value will come from the use of AI in business activities like sales and supply chain management, but companies will need to recognize ways of working should change to enable AI adoption.

Leveraging the data ocean

One of the biggest challenges with data is that it can exist in siloes with no strategic framework. The advantage of an ERP system is that it provides the architecture to consolidate data so it can be useful. It is not enough, though, just to collect data. In a smart factory, data is part of the manufacturing process. However, the value of data comes from the insights it creates, the processes it can help optimize, and how it can improve decision making.

A majority of organizations have not yet successfully monetized their data. Monetizing data is the ability to earn revenue from digitizing products and services, and to share the data across the manufacturing ecosystem. In this way, information truly becomes an asset, and enables companies to create new services or start new business models.

Industrial Internet of Things

The Industrial Internet of Things (IIoT) refers to the services and applications that allow companies to integrate devices, sensors, and machines used in manufacturing. It provides a platform for gathering and processing the data that the sensors and devices record.

The value of IIoT is that everyone in the organization can have visibility of factory operations at a detailed level. The benefits of this include:

- increased process efficiency and productivity,

- improved quality,

- providing better service,

- helping with troubleshooting and maintenance.

IIoT isn’t just for “greenfield” sites. It can be implemented in existing manufacturing operations by connecting and optimizing existing infrastructure and then gradually enhancing it with new machinery. By connecting and adding sensors and services to existing equipment, companies can collect data and convert it into business insights.

Issues to address

As digitization and innovation in manufacturing accelerates, companies should realize that these new developments should be implemented together rather than as isolated solutions. Otherwise, they risk becoming “just another project”.

The issues that executive decision-makers need to start addressing is:

- which of these technologies matter for the company,

- what is the right time to start and scale these technologies,

- what changes are needed to the current operating model to see benefits from the technologies.

The last industrial revolution (Industry 3.0) involved the automation of machines and processes. The COVID pandemic has highlighted the importance of digital technologies and accelerated their role in a new industrial revolution (Industry 4.0).

1 thought on “The future of manufacturing: trends and innovation for growth”