The electronics industry has experienced dramatic changes on the customer and supplier side in the last 18 months – from sudden purchasing changes by customers to shortages of parts and components from suppliers. Given the radical changes of the pandemic, one strategic question electronics manufacturers should be asking themselves is whether they are prepared for further changes in the coming five to ten years.

While some trends have been emerging in recent years, they have speeded up rapidly and are taking industries to a new level. The changes the electronics industry has experienced comprise some technology innovations, but the pandemic has pointed to some business process areas that need to be overhauled.

Industrial Internet of Things

It’s too easy for business functions to address their challenges in isolation. Electronics manufacturers are using this technology in various ways, such as cost reduction, product innovation, predictive maintenance, increased efficiency, and improved safety.

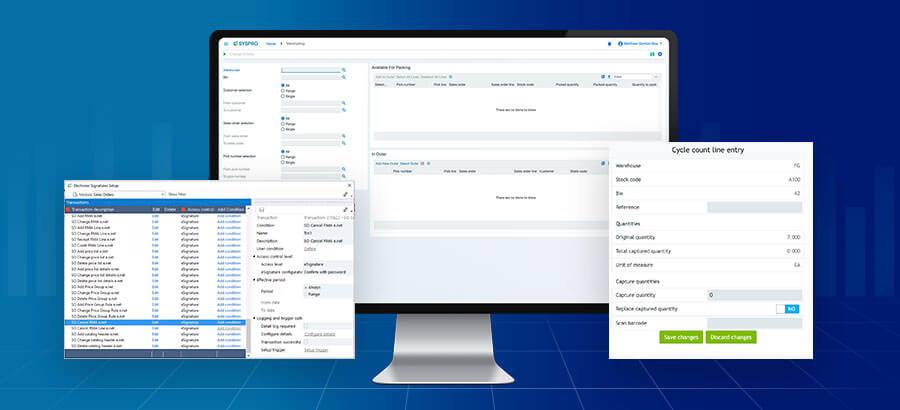

Investing in new technology is necessary and important, however many areas of business have undergone a significant change which requires investment in new or modified business processes. Several functions in the business need to be re-examined in the light of the realities of a pandemic new normal. A better path is to do it in an integrated way so that all parts of the business improve together. That is why many manufacturers opt for an ERP system to help them address their challenges.

Supplier management

The supply chain shocks of the past 18 months have shown that traditional supply chain management practices need to be reviewed. With a manufacturing-oriented ERP system, companies can track supplier capability and performance on a number of levels, including delivery performance and performance relative to other suppliers. With supplier quality management becoming important, using an ERP application can assist with the implementation of purchased goods inspection and the quality of delivered raw materials.

Product development

The product lifecycle of electronic products has been getting shorter as consumer preferences change. As a result, electronics manufacturers need to be able to introduce new products on a continuous basis. It’s standard practice to use a CAD system to design a product and then import the design specifications to the production system. But there are a large number of components in electronic products, so to ensure that design revisions are efficiently managed, engineering change control is required to review and approve changes. This is an essential requirement for managing version control and updates to the Bill-of-Materials (BOM) which specifies the raw materials, items and assembly steps required to create a product.

Manufacturing systems

Investing in IIoT will be necessary to improve efficiency and manage capacity on the shop floor. In conjunction, the management of shop floor activities will require attention so that flexible and reliable production plans can be created. A manufacturing operations management (MOM) system gives production managers visibility of current jobs and available resources. A MOM system generates accurate schedules that take into account constraints around people, machines, tooling and material to make the best use of available capacity. It also enables re-scheduling of activities when business priorities change, or unexpected events occur.

Inventory management

Keeping track of stock items as they move through the value chain has an important role in managing costs and reducing wastage. Manufacturers can benefit from an ERP solution by getting a unified real-time view of inventory at each stocking location – from expected items from suppliers, to receipt, on the factory floor, in the finished goods warehouse, and in transit.

With faster product lifecycle changes comes the issue of minimizing stock that is obsolete for new products. An ERP system can use first-in-first-out stock allocation so that older stock is used first. This reduces the chance that obsolete stock will build up.

Serial and lot number tracking improves the ability to effectively track the movement of all manufactured items through the production line and the wider supply chain. This may also be required to comply with quality regulations or with contracts for upstream customers.

Warranty management, traceability and recalls

In order to serve customers better, manufacturers need an ERP system that automates the processes for authorizing and tracking customer returns and warranty claims. This speeds up the customer returns process and enables follow-up actions such as repairs, scrap and credits, as well as charges for returns and restocking activities. The warranty information can also be used by manufacturing to improve product quality.

For compliance – whether government or customer-driven – the ability to ensure part traceability from source, through manufacture, to final destination is critical to guaranteeing product quality. This requires a traceability system that can trace back, trace forward and detail any modifications done to a product throughout its lifecycle.

Recall triggers can vary. The trigger for a product recall is usually a quality issue with raw materials or finished goods. Manufacturers should seriously consider using an ERP system that includes a recall management system. This gives access to all the critical information needed to track a suspect product through its lifecycle, and should supply the information needed to identify, isolate and action activities that occur within a predetermined recall time and ensure that regulatory reporting requirements are met. The recall system should offer reports of mock and actual recalls to assist in complying with industry and legislative requirements.

Benefits of an ERP system for electronics manufacturers

It is now critical for a business to use real-time information that is consolidated across the enterprise. An ERP system helps manufacturers to:

- optimize and automate the business;

- reduce inventory levels;

- be more effective in sourcing and supplier management;

- be more efficient in product development;

- make manufacturing operations more agile;

- reduce operating expenses;

- improve product quality;

- enhance customer service.

Electronics manufacturers who consider themselves to be future prepared realize that the pandemic affected several elements of their business and believe those changes will be permanent. Therefore, they will not only invest in new technology, but will also undertake a thorough re-examination of current business processes and practices. This will give them the agility to take advantage of opportunities that arise from the often unpredictable changes that are occurring in business, markets and customer preferences.