Manufacturers and distributors are operating in intensely pressured times as a result of COVID-19. According to a survey conducted by the National Association of Manufacturers (NAM), 78.3% of manufacturers anticipate a financial impact, while 53.1% anticipate a change in operations.

In response, many countries are looking into relief aid solutions to keep essential industries afloat. For example, the United States Federal Government through the Coronavirus Aid, Relief and Economic Security (CARES) Act is working to make funds available to help companies who are impacted by COVID-19.

Simultaneously, companies are urgently adjusting their operational strategies to increase agility, while maintaining continuity, particularly for procurement and the supply chain.

While you might feel like you are steering into a storm, there are proactive steps that can be taken to ensure you navigate safely through to calmer waters:

1. Gain greater visibility of your supply chain

Global supply chains have been disrupted due to worldwide lock-downs, and the closing of borders, airports, and ports to anything but essential items has seen procurement teams scrambling for locally-based suppliers to ensure they can fulfill existing orders and continue with new orders. To be more resilient, businesses need to be able to quickly revise their supply-chains and shift from cost optimization to supply security; and at the same time, ensure diversification of distribution, logistics, and freight channels.

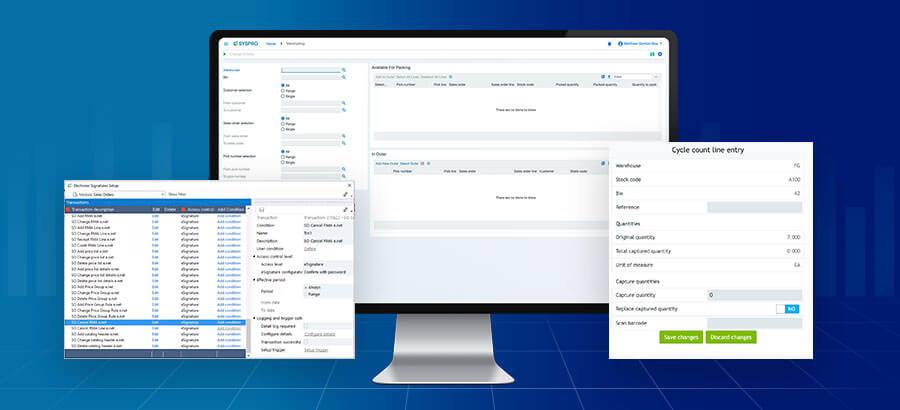

By implementing a digitally-enabled Enterprise Resource Planning (ERP) system that gives them greater visibility across their supply chain, especially inventory levels at the critical stages, procurement teams can play a significant role in solving supply chain challenges. The focus should be to more accurately calculate demand, publish new tenders and RFQs, and ensure that the right levels of inventory and raw materials are ordered and delivered, in the right quantities, and at the right price, while still helping to mitigate risk along the supply chain both now, and into the future.

2. Localize your supply chain

Reducing costs has long been a primary driver for using international suppliers from markets with lower labor costs, such as China.

On-shoring, a recent trend, is the “bringing home” of offshore manufacturing, may create a stronger localized supply chain but will most likely increase manufacturing costs, and ultimately create higher prices for consumers, but it brings with it a number of material benefits. By re-establishing local manufacturers and bringing these smaller local businesses into your supply chain, you will be helping to bring much needed financial relief to your regional and national economy, increase tax revenues and boost the job market. With time, you will also benefit from enhanced product quality and improved supplier standards.

3. Use technology to connect the remote workforce

Social distancing has become the new normal, and entire workforces, while having to remain separated, have needed to connect and collaborate remotely. Some businesses are being forced to work with half their normal staff complement, with split-teams working alternate weeks, to prevent transmission of the Coronavirus across the entire business.

Manufacturers can greatly benefit from using technology and ERP to enable their remote workforce by giving them immediate insight into business activities. Accessibility to information is critical for proper decision making in every business no matter the situation. The use of automated business systems supports the efficient management of procurement and sourcing policy changes, improved distribution and lead-time planning, and better decision-making based on relevant, and accurate real-time data.

ERP has also allowed improved visibility into stock availability, material requirements, suppliers, and outstanding orders, and spend with existing suppliers. The organization can also see the number of incoming customer orders, and gain insights into potential future orders, and see at a glance what their customer’s financial standing is with the business, prior to accepting any new orders. The power of a fully integrated ERP system cannot be under-estimated in troubled times like the present.

The way forward

We have all had to accept and adapt to the changes that this new world has brought, and these are just a few steps that can be taken to ensure your business is more agile and resilient to an ever-changing environment.

For those who have been delaying the transition to digital, the lessons we are learning together around the world, are evidence of the clear need for a transition to a digitally smarter business environment.