The future direction of supply chain management and collaboration will be determined by the impact of digitalization on the supply chain. Every analyst and forecaster is making that general prediction for the supply chain of the future. At the same time, customers and consumers are changing the way they order goods and services, forcing companies to adopt new pricing and delivery models.

With potentially disruptive changes likely to occur throughout the entire supply chain, businesses need to start preparing for new supply chain philosophies and practices to accommodate new business models and innovations, some of which may not be entirely clear or obvious at the moment.

The old vs. new supply chains

The focus of supply chain management in the past was on driving cost savings and efficiency, and improving forecasts based on historical data. Classical supply chains tried to optimize a set of linear, vertically integrated processes.

The model for future supply chains will be an ecosystem of suppliers and technologies using information as a backbone to gain real-time visibility into processes and items in the supply chain, thereby improving decision-making and enabling better responsiveness to changing conditions.

Tools to support the future supply chain

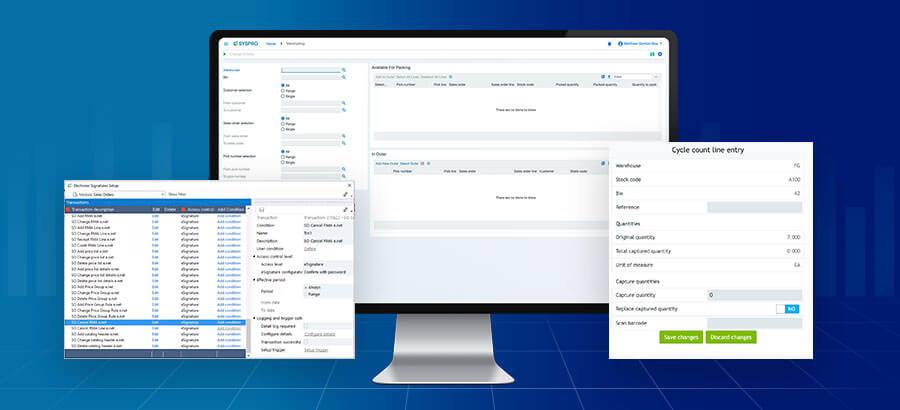

With all the unpredictable and disruptive changes that you will need to anticipate in the supply chain, businesses should be looking at tools that can support their future requirements. These tools should allow greater ‘digital capability’ to:

- improve collaboration at both the customer and supplier ends.

- provide the information and visibility of products and parts throughout the supply chain.

- enable the procurement function to become more strategic.

- streamline fulfillment at all levels.

Supplier collaboration

For some time, forward-thinking organizations have been trying to get their suppliers more involved in the early stages of the product life-cycle – the design and development processes. In the past, businesses used bespoke systems to achieve this. As the adoption of web platforms grows, this will propel online collaboration and transacting between an enterprise and its suppliers, streamlining the process of document handling and exchange. Companies can use these online portals to request quotes and other information from suppliers, making collaboration more transparent. This information can then be integrated with downstream functions of the business, ensuring better alignment and driving towards a digitalized organization.

Procurement

For a future supply chain, procurement can be improved by becoming more digitally enabled. Strategic sourcing is not a new concept, but a digitally transformed procurement function offers the potential for competitive advantage. A digital capability in procurement is not just about improving the sourcing of raw materials and parts, but also optimizing and automating the management of sourcing strategies and supplier policies, helping to improve governance and oversight, and reducing risk.

Inventory and fulfillment

As the volume of data increases in the supply chain, there will be more information to improve inventory management. The sales and operations planning function can use this information to balance supply and demand, and to decide what inventory items are needed when and where.

In the warehouse, order fulfillment can be improved by having more accurate tracking of the location of items. In addition, automating and standardizing the receiving, put-away and picking processes can shorten fulfillment times, and reduce operating expenses.

Customer interaction

A supply chain cannot start without a demand signal. By providing the signal with more accurate actual and forecast order information, a business can plan for requirements further down the chain and with more acceptable variances.

One way of achieving that is to have digital tools that will allow companies to collaborate strategically with customers to improve order forecasts and replenishment, so making estimates more accurate, and reducing the risk of errors.

For the consumer market, businesses will need to invest in technologies that will enable them to respond better to requests and demands across multiple channels. An e-commerce portal is one obvious channel, however, being able to monitor other channels such as social media could provide early notification of changes in customer preferences.

It doesn’t end there. Once an order is confirmed, the communication with the customer needs to continue so that they have full visibility of their order status and can stay informed of changes to the dispatch and delivery of orders. Customers should also be able to have access at any time to information about orders, to request changes, and receive alerts using self-service tools.

How the future supply chain will work

In his book, The Fourth Industrial Revolution, Klaus Schwab notes that this new revolution will “reshape the production, consumption, transportation and delivery system”…in other words, the supply chain. It is becoming clear that one effect of this revolution will be the volume and flow of data at all levels in the supply chain. It will be possible to use the flow of information to reduce uncertainty about demand and have greater visibility of items moving through the chain. Collaboration in the form of data sharing will become a standard operating principle of the future supply chain. This will make supply chains more transparent as more participants access and engage with information. Schwab also comments that we don’t yet fully understand the ramifications the revolution will have, so businesses need to start considering the tools and technologies they will need to cope with the potential disruptions.