The disconnect between Sales and Operations in manufacturing companies is so common that it is almost a cliché. I’ve experienced it myself and I’ve met plenty of people at other companies going through the same struggles. Maybe you see some of this in your own company.

Sales perceives Operations as incompetent, unable to deliver the right products at the right time. Operations perceives Sales as unpredictable, overly demanding, and unreasonable. And customers are unhappy because they’re being shorted.

I lived through this when I worked in Operations at a food manufacturing company. Life was reactive and chaotic. Our production schedules were constantly and unexpectedly changing, which was really inefficient. Purchasing was always expediting purchase orders. Paradoxically the plant and warehouse were jam packed with inventory and yet we were still shorting customers – because it was the wrong inventory.

Eventually we evolved to a better situation where life became more predictable and happier for everyone. Sales and Operations actually got along with each other and worked together to fulfill customer orders. Imagine that!

How did we do it?

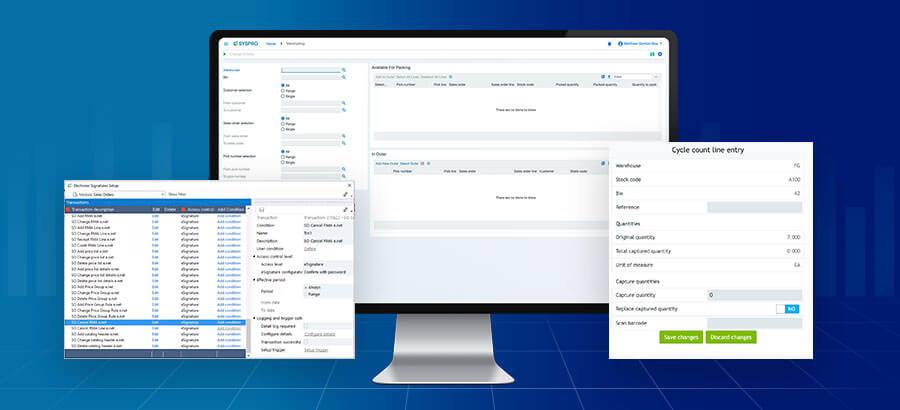

One of the tools we used in SYSPRO to bring Sales and Operations together in a way that made everyone happy, including Finance, was Inventory Forecasting. The system can generate forecasts based on past sales, and Sales can easily review and edit the system-generated forecasts if desired.

These forecasts give more predictability to Operations departments such as Production and Purchasing. Thus they can produce the products that customers require more efficiently and less reactively.

How does a forecast help Operations?

SYSPRO passes the forecasts through Requirements Planning which crunches lots of supply and demand data and recommends what Production and Purchasing should make and buy.

By using SYSPRO’s inventory Forecasting and related modules better, it eventually dawned on Operations people that if we produce to the forecast, Sales (and customers) will be happier. This resulted in fewer last-minute production schedule changes and enabled us to do longer production runs and work more efficiently.

It also dawned on Sales that if, with SYSPRO’s help, they provide a half decent forecast, then Operations can fulfill more customer orders. With fewer orders shorted, the Sales team were cashing bigger commission checks.

Finance was happy too because we carried less inventory and did less expediting.

One day, a senior Sales manager was in my office and gazed through the window into the plant, where the workstations were running very smoothly – predictably, and almost boringly. In a nostalgic voice he said “I remember the exciting old days when we were always fighting fires and I would go into the plant and give orders to change the production schedule like a General on a battlefield! Sometimes I almost miss those days.”

I laughed and said, “I don’t!”