We can all agree on the importance of food safety. We want to trust that the food we put on our plate is clean and nutritious. Yet, we still commonly see headlines containing food contamination issues such as the November 2019 Canadian romaine lettuce recall linked to lettuce harvested in Salinas, California.

These issues can become substantial burdens for the public, causing illness or worse. Health Canada cites such numbers: 4 million Canadians (1 in 8) get sick, over 11,500 are hospitalized, and 240 die each year from foodborne illnesses.

The Canadian Food Inspection Agency (CFIA), as well as the Food and Drug Administration (FDA), can mandate a recall when they discover issues. Manufacturers can also voluntarily issue food recalls in conjunction with these agencies. As you can imagine, food recalls bringing huge losses to businesses. One food recall can destroy a brand’s reputation, and smaller companies are often unable to recover due to financial damages and brand degradation. Manufacturers typically invest heavily in their brand and it only takes one high-profile incident to put them out of business.

This is why food safety compliance is important for manufacturers. While the paperwork burden typically associated with compliance has been difficult historically, this obstacle can be eliminated with the help of modern software. Compliance is a complex subject, seemingly growing denser every year. It is also expensive – annual compliance costs can be as high as 25% of operating costs.

Spreadsheets can only get you so far

Many manufacturers that I speak with manage compliance requirements by manually maintaining spreadsheets or form-based documents. Perhaps some semi-automation has been custom built by an Excel-savvy team member, but the process typically depends on a person collecting handwritten forms, deciphering what was written and then manually entering it.

If this sounds familiar, you have probably experienced a few of the problems associated with this method:

- It is inefficient – having skilled people performing data entry is not a good use of their talents.

- People are prone to error – number transpositions, inconsistent categorization, missing timed checks or “remembering” events after the fact are very common in manual form-based data collection.

- Writing on, moving, storing and searching through paper-based forms is expensive in time, material and storage costs.

- It’s complex. Food and beverage regulations are often changing, and the onus is on the business to stay up to date. Any changes in your SOPs and all associated HACCP plans must be updated. Navigating the complicated regulatory landscape can be difficult and time-consuming. As cited in Thomson Reuters Cost of Compliance 2018 Report, “53% of Compliance Managers say their reporting system lacks a comprehensive view of compliance.”

Compliance automation

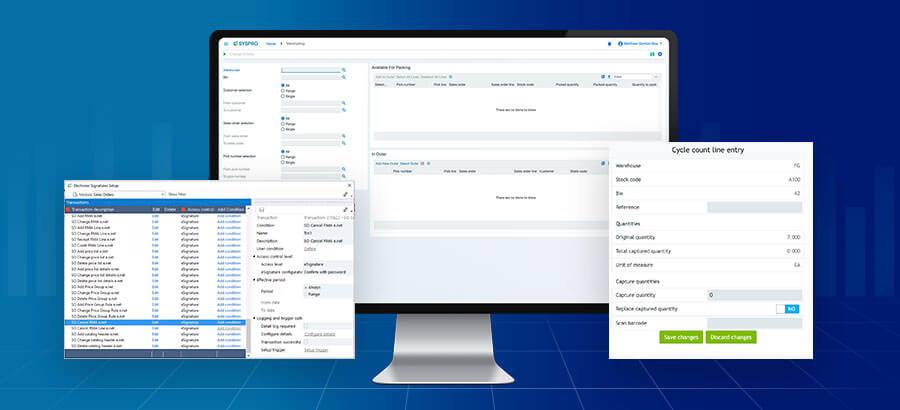

Faced with these challenges, food, and beverage manufacturers are turning to compliance automation to meet their regulatory requirements and streamline compliance processes. It leverages all relevant information from the manufacturing process and automates many manual tasks completed by your compliance staff. Compliance automation also reduces complexity for your operation in helping you meet these requirements.

Benefits of compliance automation

Compliance automation solutions offer many advantages over traditional, manual methods. Here are the benefits:

Improved Efficiency:

It is more efficient when data collection and categorization is automated. These are tasks that can be done quicker with software. One such example is the automatic collection of batch records. This means your staff can focus on activities that drive profit to the business, rather than low-value data management tasks. As mentioned previously, when performing repeated tasks, a human will eventually err. Mistakes can range from transposing numbers or unreadable comments to potentially missing an entire report that had to be done at a certain time. These can easily be avoided with software that enforces process, validates data and provides selection lists for categorization.

Traceability:

When compliance automation software is integrated with your ERP, you can have end-to-end support documentation with the traceability of your processes. From raw material testing to the final product, the ERP can give you real-time visibility of your products and the associated compliance records. If an audit is required, detailed reports can be generated typically in minutes.

Root Cause and Action Plan:

Another benefit of system integration is that you can assess the root causes of non-conformance, correct them and create preventive action plans to decrease the likelihood of the problem resurfacing. Paper forms and spreadsheets make it much harder to get the visibility you need to resolve the issues.

Lower Costs:

A surprisingly large number of companies have no idea how much compliance-related activities are costing them. They are generally categorized as an assumed cost of doing business and wind up in the “overhead” bucket. All these improvements can lead to an increase in profitability based on savings realized through the elimination of paper and physical storage as well as saved time.

Audit Trail:

For many companies using a paper-based system, compliance records are stored in binders, which are in turn placed in bankers’ boxes, and then stored in a back room. Finding specific documents related to an investigation is extremely time-consuming. Maintaining a log of records to chronologically capture the sequence of events is important to exhibit compliance adherence and is what database-driven compliance software is extremely efficient in performing. With accessible logs and automated reports, businesses hold their integrity and accountability, while mitigating any potential losses.