Manufacturers increasingly turning to data and analytics, from an ERP system, to support business initiatives. Data is after all the fuel that runs the Fourth Industrial Revolution. It is needed to provide more accurate awareness and visibility over operations, and by using data and analytics effectively an organization can become more responsive. The delivery system that collects and stores data for decision-making must ensure that information is timely and accurate and makes information accessible and understandable.

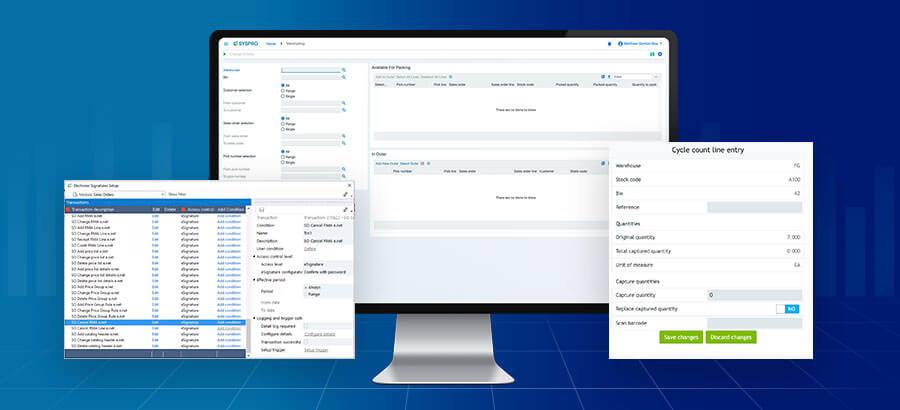

Organizations have spent several decades trying to find software applications to provide decision-support capabilities. In most cases, there has been a succession of tools that worked in some cases but were not broadly successful. The reason is that staff had to learn a different user interface (UI) for analytical tools to the UI they were accustomed to in their day-to-day operational activities when working with an ERP system. So if an ERP application can deliver all the information that staff need for decision-making then they can have the insights needed to take the necessary actions.

Challenges to using data

Many manufacturers are data-rich but when it comes to using it they are insight-poor. This is because they do not have the appropriate IT architecture for staff to use data to run their operations better and give better customer service.

Often organizations do not have the high-quality, trusted systems to provide analytics for reporting and decision support. The challenge is that data is not seen as a key asset that requires quality control and governance.

In most companies, the first mile of data and analytics has occurred — amongst executives, and in marketing and sales. The issue is to address the last mile problem and make adoption more broadly across the organization.

In other situations, businesses face various data challenges.

- Management reporting and scorecards are used but prepared manually

- The visibility into business operations is limited or non-existent due to lack of access to information

- In a rapidly changing business environment, the information needed to quickly know what is going on is unavailable

- IT developers spend a lot of time creating custom reports, which need to be redone with each business change

- Reliance on spreadsheets means too much time is required to manually extract and reformat data which can also contain errors

How an ERP system provides the framework for data and analytics

An ERP system contains all the essential data that personnel need to make decisions about their processes and operations. Whether it’s information about suppliers, procurement, inventory management, factory operations, sales or service, an integrated ERP solution has the data necessary to make decisions. It then becomes and question of how to present that information.

In addition, an ERP which is extensible and enables integration with third-party products using industry-standard technologies, provides an environment in which data from various sources can be consolidated. So shipment information from a logistics partner can be integrated and consolidated with supplier orders to provide a fuller picture of when goods are expected to arrive. In another case, Internet of Things data from the factory floor can be collected and aggregated with data about manufacturing jobs to give more detail about production operations.

Steps to building a data and analytics capability

To set up a functional data and analytics capability involves several steps.

Strategy

- Understand business priorities and how data can support them.

- How data can be used to link business goals and metrics.

- Start promoting data as a key asset.

- Decide on an architectural framework for managing the data, and the software tools that will be needed.

- Identify the roles and competencies needed to deliver and maintain the environment.

It is important that the tools selected can provide relevant data in real-time, with the ability to drill down to see the detail underlying the information.

Culture

A Forrester Research survey reported that organizations that invest in a data-oriented culture can achieve higher productivity, increased innovation, and better customer experiences.

- Focus on increasing data literacy. The Forrester research predicts that 70% of employees are expected to work with data by 2025, necessitating a basic level of data literacy — the ability to explore, understand and communicate with data.

- Set up structures, processes and roles for governance

Review and refine

- Evaluate value and get feedback

- Reassess strategy

- Make changes accordingly

Improving visibility

A survey of CFOs noted that among their top four priorities was ensuring greater visibility into performance and operations. This is an initiative that will require much greater use of analytics at all levels of the organization. By making use of the large volume of data that is created and stored in an ERP system, covering all areas of the business, with a culture that promotes the importance and use of data for decision-making, manufacturers have the foundation on which to build a trusted and responsive data and analytics