Global manufacturing and distribution sectors are set to shift. Since the start of the pandemic, industries have had to face increasing pressures, from supply chain disruptions to a shortage of business system accessibility and a lack of worker availability. While the ongoing struggle for raw materials continued under national lockdowns, the pandemic also acted as a catalyst for Industry reinvention. A good example of this took place in South Africa. During the national lockdown, consumers became increasingly reluctant to go into stores and instead opted to shop online. In order to capitalize on this opportunity, a local beverage wholesaler sold its products directly to customers through a third-party e-commerce website. To have real-time visibility of their stock availability, the business integrated an API into their existing ERP system.

As you can see, many businesses thrived through innovation to meet the demands of the ‘abnormal’, but we wanted to really understand the longer-term impact of the pandemic. An online survey was therefore shared with industry professionals of different managerial levels within each of our key regions. This included the United States, Canada, EMEA, and APAC. The survey was conducted in August 2020 and was directed to both office workers as well as operational workers in departments including operations, the office of finance, IT, logistics, marketing, and sales. Here are some of the key insights and emerging trends:

1. Manufacturers and distributors are making provision for the remote workforce

Unsurprisingly, our survey revealed to us that 37% of companies were unable to provide the remote work capabilities to employees that were required. This included back-office positions such as administrative functions as well as front end operations. This indicates that many manufacturers and distributors are still heavily reliant on manual inspections, manual recording, and disconnected processes.

Moving forward, 73% of businesses stated they would need to invest in capabilities to facilitate remote working. And while 45% of businesses have realized that they could lose talent in the future if they do not embrace remote working moving forward, the onus will be on leaders to ensure that the all-new and ‘improved’ remote workforce have the necessary skills to utilize the cloud and other collaboration tools to the fullest.

2. The rise of new manufacturing hubs and the re-shoring of supply chains

Rewind a few months back, and you will find that most supply chains were heavily integrated and increasingly reliant on foreign raw material. There were a number of benefits to looking offshore – including cost reductions and efficiency. This of course often came with the price of quality and control. As soon as global lockdowns resulted in supply chain disruptions, businesses needed a new plan.

Our survey revealed that 42% of businesses will near-shore or re-shore manufacturing operations. This reconfiguration of supply chains has both an impact on localized requirements as well as dual sourcing policies for supply certainty. Some of the new manufacturing hubs that are rising are the Philippines, Hungary, Costa Rica, and even Columbia.

3. A renewed interest in Industry 4.0

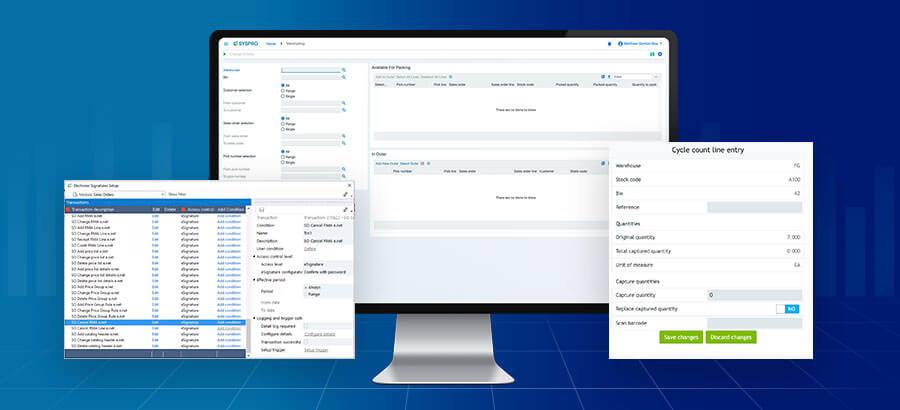

The pandemic has proven that manual and disconnected processes can spell the end of business operations. A report by Mckinsey echoes this by stating that the role of Industry 4.0 becomes even more critical on the backdrop of a crisis such as COVID-19. Players utilizing digital solutions are better positioned to weather the storm, having moved faster and further than their peers during the crisis. While manufacturers and distributors have been slow to adopt the cloud due to a number of reasons, some due to the interconnectivity required to operations directly on the shop floor, and others due to the regulatory requirements placed on their industry, things are now changing. In fact, because so many businesses still rely on manual processes, 29% of businesses stated that they would be pursuing cloud-based business systems moving forward.

Emerging trends shaping the future of the factory

With the advancement of the remote workforce, the global appetite for re-shoring, and a renewed interest in cloud technologies, the world is now entering an inflection point. We are witnessing the rollout of the ‘factory of the future’. Technologies that will shape this shift will be the uptake and adoption of business process automation, collaboration portals, and messaging gateways.

Read more about SYSPRO’s study into how manufacturers handled the shift during the pandemic.