When sitting down to a meal, do you ever take a moment to think about where the food came from? Sadly, I think most people would say the local supermarket.

On a larger scale, a study by KPMG found that nearly half of global manufacturers don’t have any visibility past their direct suppliers. Meaning they cannot see beyond them, to their suppliers’ suppliers. This can have huge implications, especially in industries where traceability is required (such as food and pharmaceutical).

Let’s use a meat packaging plant as an example. The plant buys meat from a supplier, which sourced meat from multiple farms in an area. The packaging plant records transactions with its supplier, but has no idea about the cleanliness and health history of the farms. Knowing the source of the meat can assist when there is an incident (such as contamination) within the supply chain, often, the negative effects of which are felt by the customer (you, at 2am).

For transparency (and health reasons) identifying the location of each point in the journey food travels, from farm to fridge, is essential. Simon Thompson, the Director of Commercial Business Development at Esri (which specialize in GIS Mapping Software) suggests the use of mapping. Linking geographic information (all the locations that the meat came from) to non-spatial data (the name and lot number of the cow, and the firm processing it) can assist food chains to become more easily accessed and tracked.

Geographic information can be obtained using a Global Positioning System (GPS). All smart phones, and probably most farming equipment, have a built-in GPS. These systems collect and log location data automatically. The data is then transformed into information about where people, livestock and products are located and how they move between locations. If a farm or factory has an outbreak, the impact and implications can be assessed quicker and measures taken to correct future problems.

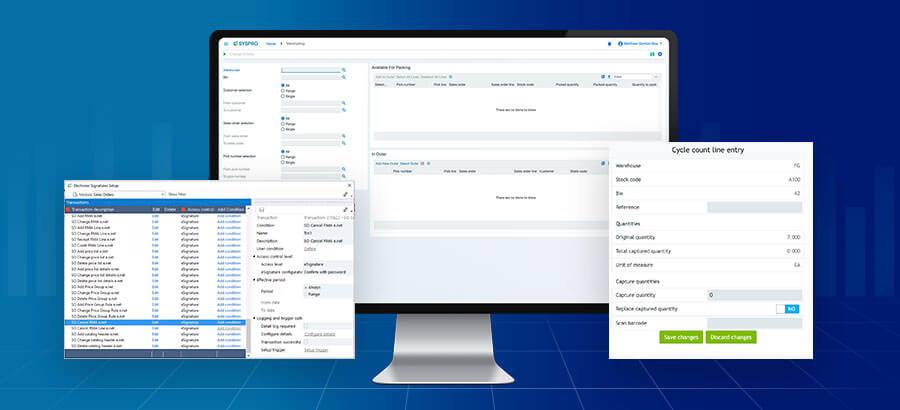

By now, you should be aware of SYSPRO’s Lot Traceability module and inspection features. This is standard with any ERP offering. But what about the ability to link to geographical data?

Within SYSPRO, you can store the geolocation against a supplier (as well as customers) and link to maps such as Google Maps. This is standard but with a little scripting, you can add geolocations and get SYSPRO to find the address. You can also make use of other SYSPRO Power Tailoring facilities, such as custom form fields, the Application Builder, form actions, customized panes and flow charts to capture, link to and document geographical information. Custom form data can be used in reports or dashboards which will allow visibility of the supply chain network, not only of the supplier but right through to the customer.

Additionally, you can store information about a supplier’s supplier, their distributors, vehicles used and even their children’s birthday, by using the Contact Management System. The possibilities are endless.

You cannot realistically take a tour of your next meal’s supply chain network. However, by having visibility of that network, customers can be assured that you (as a supplier) know where to look should anything occur. There is accountability, at all stages. Those using these features, may sit down to their next meal and appreciate the journey the food has taken to get to your plate.