When it comes to selecting software for the enterprise, decision-makers must choose between multiple solutions. This may include choosing software for managing the enterprise (an ERP system), for supply chain management (SCM) or for customer relationship management (CRM). What do these different systems do to help a company, how are they different, and should they be separate or integrated?

What is ERP?

In 1990, technological research and advisory firm, Gartner, created the definition for enterprise resource planning (ERP) as:

“an integrated suite of business applications. ERP tools share a common process and data model, covering broad and deep operational end-to-end processes, such as those found in finance, HR, distribution, manufacturing, service and the supply chain. ERP applications automate and support a range of administrative and operational business processes across multiple industries”

At the core, an ERP system unifies finances, including the general ledger, accounts payable, accounts receivable, and financial reporting. Many also extend to inventory management, order management, procurement, and production. On the production side, operational processes will include:

- materials planning,

- work scheduling,

- labor and material costing,

- shop floor management,

- plant capacity management,

- traceability

What does an ERP offer?

Gartner viewed ERP as a platform for business process efficiency and standardization. An ERP provides a centralized, integrated business solution that automates business functions, operations, and processes. Because information is centralized in one system, an ERP eliminates duplicate entries and maintains the latest, most up-to-date data on a single platform. This, in turn, can improve employee and operational productivity by reducing manual tasks, and saving time, resources, and costs. It also streamlines and integrates processes between departments. Having all information located in one source gives decision-makers access to actionable data on multiple activities. ERP systems can be customized to a specific company’s requirements and are scalable.

ERP systems emerged out of Materials Requirement Planning (MRP) – the planning and scheduling of inventory for the manufacturing process. But an ERP goes beyond MRP – connecting and integrating all the different aspects of a business into one database, allowing manufacturers to organize tasks and processes, as well as share production information across the entire organization.

For manufacturers and distributors, an ERP system has a comprehensive inventory tracking system to help them control and manage inventory. This makes it easier to know what raw materials have been consumed, what on-hand materials have already been assigned to a specific job, and what items are getting low or out of stock. This enables the procurement department to know when new purchase orders have to be placed.

Procurement can be a complex process in a manufacturing environment. An ERP system streamlines it by using historical data and information about production requirements to improve the sourcing of items with long lead times so that materials are ready when production needs them.

What is Supply Chain Management?

SCM systems are used by manufacturers and distributors to manage the flow of goods from the sourcing of raw materials to delivering the finished goods to the customer.

What does an SCM offer?

By having data about materials and products as they move through the supply chain, businesses are better able to coordinate operations, improve efficiencies, forecast and plan better, and ensure that customers get what they ordered on time and in full.

What is Customer Relationship Managament?

CRM software is used to enhance customer relationships. It is an important tool for sales, marketing, and customer support teams. A CRM manages and centralizes customer data at every stage in real-time to provide a holistic view of the customer base.

What does a CRM offer?

A CRM manages the interaction between customers and a company. This covers the entire range from acquisition of a contact to proposal, the buying journey, sale and after-sales service. It helps sales and marketing to build buyer personas and segment customers, generate insights, and even get data from other digital sources such as social media. For service teams, it allows staff to create cases to handle problems with products after a sale and improve the customer service experience.

Combining ERP, SCM and CRM

Combining an ERP and SCM system can help manufacturers in several ways, including:

- better inventory planning and management,

- allowing procurement to make better decisions about purchasing and selection of suppliers,

- managing complex supply chain networks more efficiently.

An ERP system focuses on business management to improve the efficiency of the business system in areas such as procurement, inventory control, delivery, and billing. By integrating with an SCM system, an ERP solution has visibility of the entire inbound and production processes.

In a way, CRM is the opposite of SCM. An ERP and CRM system unifies the data around customer interactions. Customer data is valuable and by integrating it with an ERP, it can be made available to other parts of the organization.

In 2016, Gartner added a new term – Postmodern ERP – in which it identified two categories of ERP strategy: administrative and operational.

The administrative side focuses on financials, human capital management and indirect procurement – old ERP. The operational side is how manufacturers and distributors extended their ERP into areas such as manufacturing and supply chain, to maximize operational efficiencies. In other words, new ERP including the customer and supply side.

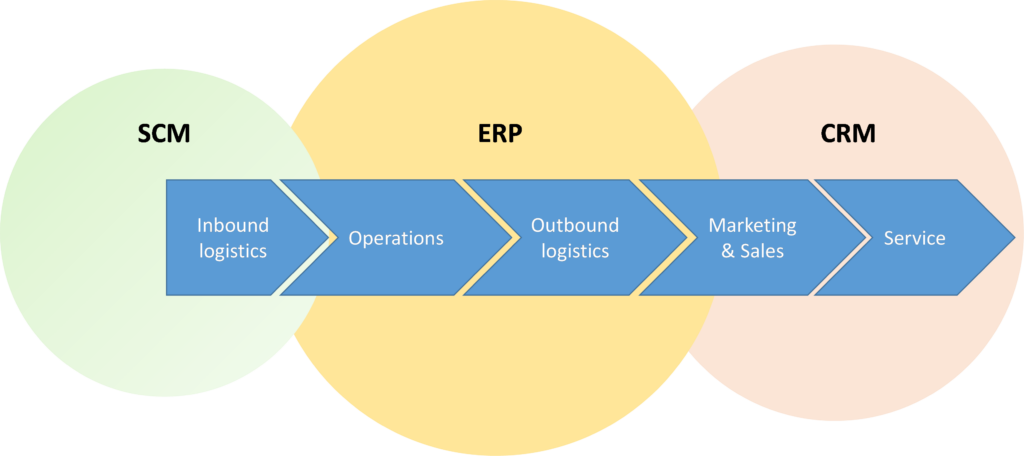

SCM focusses on supplier relationship management. CRM is about customer relationship management. ERP is about business and operations management.

By combining them, all the data in an organization is collected once during the initial transaction, stored centrally, and updated in real-time. This combination makes for a highly effective tool for comprehensive business management.

Figure: The Value Chain Framework with ERP, SCM and CRM

The final argument for an integrated ERP, SCM and CRM comes again from Gartner, which referred to the Fourth Era of ERP in 2020. This goes beyond resources and planning in the enterprise, into a wider ecosystem that encompasses customers and suppliers, where:

“The need to create, manage and understand data is paramount.”

To get value from data, it therefore makes sense for the ERP, SCM and CRM to be unified.