Smart Factory Software

DMI chooses SYSPRO ERP for Smart Manufacturing:

Make smart factories a reality with SYSPRO ERP

Using smart factory software: The Power Trio

SYSPRO's ERP capabilities helps you to thrive in Industry 4.0

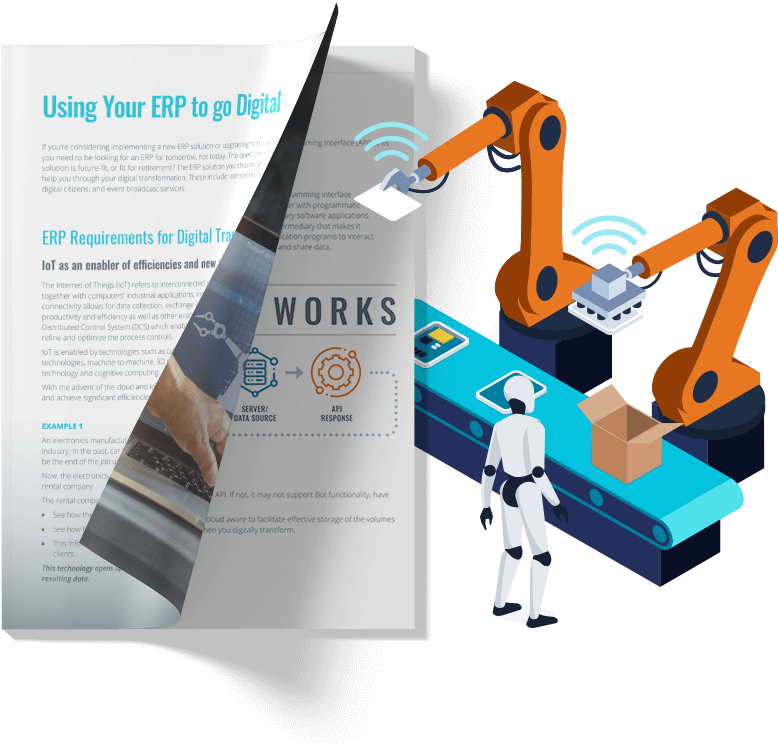

- Artificial Intelligence

- Internet of Things

How SYSPRO's smart factory software can work for you

Get a 360° view of production with SYSPRO MOM

- Plan: Resource Management, Detailed Scheduling, Materials Planning, Capacity Planning, Online Production Plans, Interactive job lists

- Track: Configurable Terminals, Job Management, Time and Attendance, Real-time Tracking, Performance Monitoring, Supervisory Control

- Automate: Over 140 Native Drivers to the most common PLC/IO Devices, Automatic Data Collection, Human Machine Interface, Data Management

- Analyse: Factory Performance, Employee Performance, Equipment Performance, Product Analysis

- Optimise: Instant Messaging, Configurable Alerts, Issue Management, Paperless Shop, Overall Labour Effectiveness (OLE), Overall Equipment Effectiveness (OEE), and Total Effective Equipment Performance (TEEP)

High-level solution architecture overview

A variety of technologies are required in the smart factory software for high automation and integration in manufacturing processes

Connect various add-ons for integrated benefits

Our smart factory software leverages cutting-edge technologies to streamline operations and optimize production.

- Payroll: Support your digital workplace

- Label Printing: Integrated label printing

- Document Management: Audit and access control

- Preventative Maintenance: Plant asset management

- Quality Control: Extended quality management

- Inventory Control: Extended inventory management

- Process Control: Drive continuous improvement

- Build & Analyze Reports: Custom reports & applications

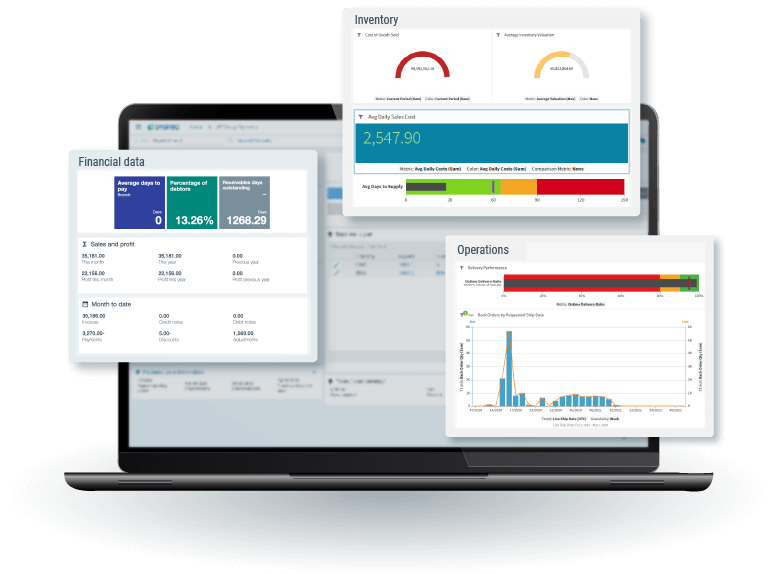

Integration & module syncing in smart factory software

Outbound integration Modules

Inventory Management

Inventory Master, Inventory Warehouse, Inventory Warehouse Control

Materials Planning

MRP Forecast, MRP Suggested Jobs, MRP Suggested BOM, MRP Routing, MRP Suggested Requirements

Sales and Purchasing

Customers, Purchase Order Header, Purchase Order Line, Sales Order Header, Sales Order Liner, Suppliers

Resource Management

Employee Master, Machine Master, Tool Master, Work Centre Master

Definition Management

BOM Master, Routing Master, Production Jobs, Production Job BOM, Production Job Routing, Sub Jobs, WIP Master

Inbound integration Modules

Time Management

Labour Hours, Machine Hours, Non-Productive Hours

Materials

Material issues

Operations

Operation Quantity, Operation Scrap, Operation Status

Production

Production Job Start Date, Production Job End Date, Production Job Line Start Date, Production Job Line End Date, Production Job Receipts, Production Job Scrap

Scheduling

Scheduled Calculation Method, Scheduled Machine

Success Stories

Amongst all the software I looked at when we began, SYSPRO was the one that stood out as an ERP that understood the manufacturing process and can integrate easily with all other systems. By building our digital manufacturing facility, with SYSPRO at the heart of it, we’ve brought to life how digital automation can save time and costs across the manufacturing process. I can’t speak highly enough about it.

The SYSPRO Mobile application has eliminated the administrative headache for our services department. Access to immediate, detailed history at the click of a button has completely revolutionized this area of our business. We are able to respond immediately to customers and resolve issues straightaway

Learn more about smart factory software

Metal fabricators succeed when they can provide a high-quality product using efficient...

Read Blog >>

Most of the top metal shops are now under the constant surveillance of ERP software...

Read Blog >>

Future-Proofing your Factory:

A strategic approach to Smart Manufacturing

Get it right first time with the right solution to meet your business system needs.

A successful ERP solution is the foundation on which companies can launch new initiatives, streamline and improve existing operations, reduce costs and grow the bottom line.

The SYSPRO IDEAL Implementation Methodology is a single, worldwide, scalable, structured and phased implementation approach that consists of predefined inputs, activities and outputs to deliver a solution on time and on budget.