The role that ERP systems can take in helping IM&E

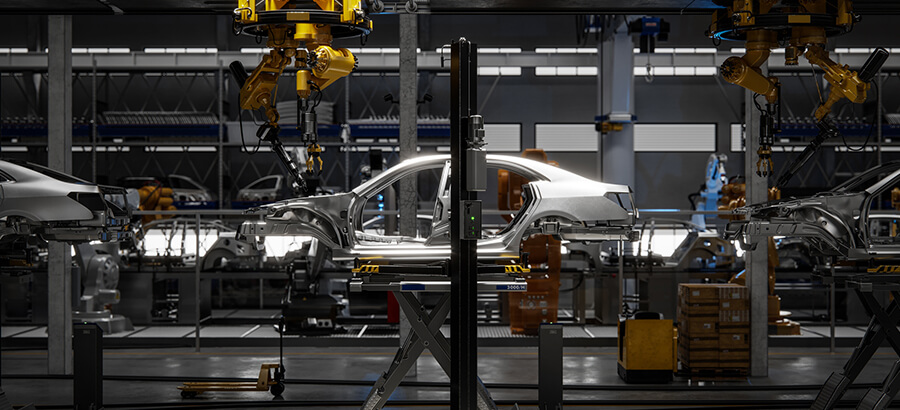

There’s no doubt that the COVID pandemic has led to major changes in the way companies work. It has also emphasized how fragile supply chains really are. Manufacturers have realized that while they may aim to be stable, what they really need is to be agile. How rapidly can you adapt if something changes quickly … Read more